Solution

Turning Solutions

1. Listening

To offer a perfect product, a comprehensive understanding of our customer’s needs is imperative. We believe this to be the most critical phase of the project and we commit our best efforts to defining a clear and consensual objective with our customer:

- Assortment of parts to be processed and required features.

- Processes to be performed on these parts and frequency of each process.

- Critical aspects of the process and other secondary aspects.

- Desired balance of time, quality, tool costs, production shifts, and machine life.

- Operator qualification.

- Space limitations in facilities, foundations, smoke management, noise, etc.

- Investment capacity.

2. Proposal

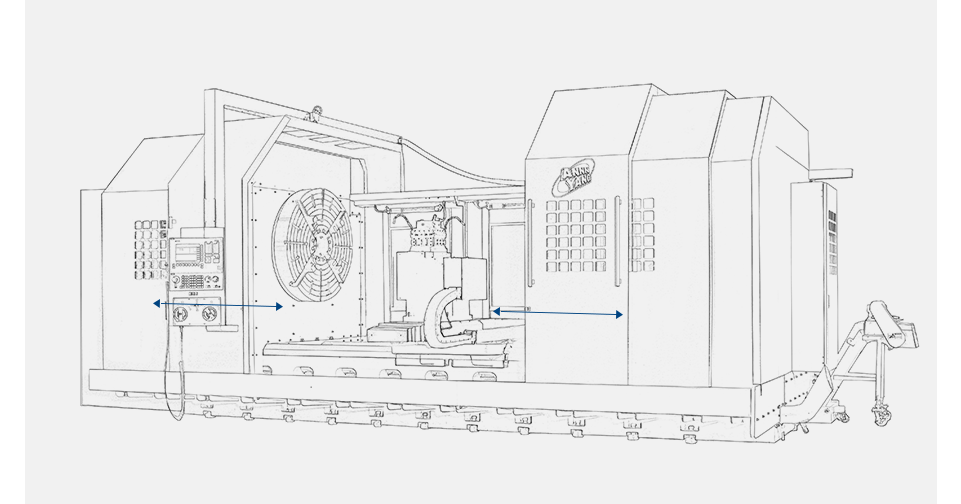

Turning Solutions

2. Proposal

Each requirement is studied in depth, alternatives are analyzed, and pros and cons are discussed until we design a solution that fulfills each need. A first solution to the client is proposed and an open dialogue follows until we reach the optimal contractual and operational architecture:

- Balanced machining processes.

- Selection of tools and costs.

- Design of PLC systems.

- Ideal machine layout.

- Installation requirements and other auxiliary elements.

3.Solution

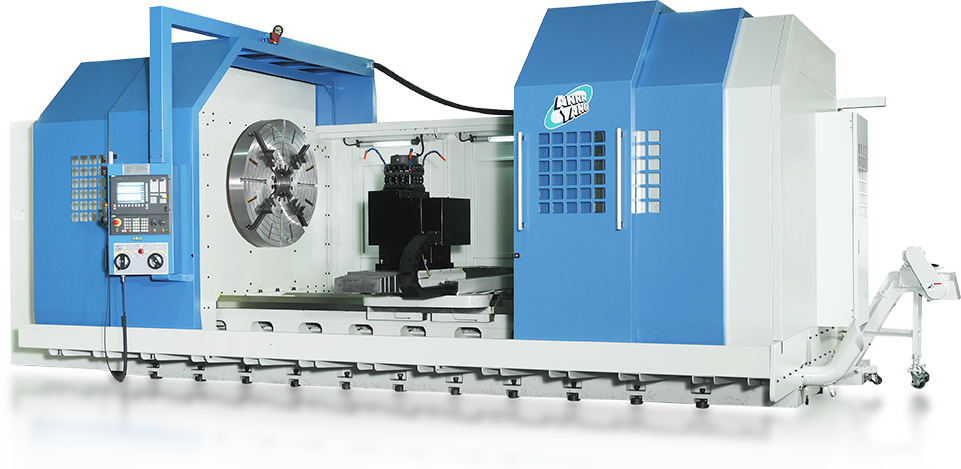

Turning Solutions

3. Solution

Much care is taken to listen to our customer’s requirements and in the proposal, however there are always aspects that need to be refined when conceptualizing the solution. In this important phase, we help clients visualize these concepts by preparing 3D models of the proposal. We simulate machining processes and display them by video. We can develop a ROI analysis, so that we agree on a solution that satisfies our client’s quality, cost and deadline requirements.

4. Execution

Turning Solutions

4. Execution

Once the precise turning solution has been clarified and agreed upon, our Mechanical Engineering Dept. develops the machine models and the corresponding assembly plans, in order for the customer to approve them. This will be the time when our expert engineering and production team carries out its work:

- Experienced partners for our cast and mechanically welded parts (European suppliers only), closely monitored by demanding Annn Yang professionals.

- We only include leading brands of commercial components.

- Expert and multidisciplinary assembly teams.

- Software programming customised to the customer’s needs.

- CE user and maintenance documentation, detailed and easy to use.

- Training provided by experienced engineers, with special empathy towards the future operators of the machine.

5. Operation

Turning Solutions

5. Operation

Once the machine is completed and in perfect working order, it is imperative that the required full production of the machine is met in the shortest possible time. Annn Yang offers knowledge and experience, and with the specific knowledge of the customer’s process on its products, the machine operators can quickly become independent and achieve the highest productivity levels:

- Training and production support in the first few working days.

- Support in the programming of machining of various parts.

- Spare parts management and preventive maintenance service.

- Online assistance with queries in the weeks that follow.

6. Results

Turning Solutions

6. Results

Our machines are designed to have minimum maintenance costs. Our machine availability standards after one year are historically excellent.

Send product inquiry to us now!

Send product inquiry to us now!

- We have a vast stock of spare parts to minimize machine stoppages in the event of any problems.

- Our service team will always be on hand by telephone, remote service or by visiting your facility in person.

- The service life of Annn Yang machines can reach up to 40 years, even under the harshest of working conditions.