- Home

- FAQ

- About Machine Models

- What’s the difference between Conventional manual lathe (G), Variable Speed Lathe (VS) and Clutch Lathe (M)?

What’s the difference between Conventional manual lathe (G), Variable Speed Lathe (VS) and Clutch Lathe (M)?

What’s the difference between Conventional manual lathe (G), Variable Speed Lathe (VS) and Clutch Lathe (M)?

Annn Yang produce 3 types of manual lathes (without CNC control system):

- Model "G"------- Conventional Manual Lathe

- Model "VS"------ Variable Speed Lathe

- Model "M"------- Clutch Lathe

Model "G"----Conventional Manual Lathe

This model G is completely conventional manual lathe. Different spindle speeds are changed by different gear combination. Operators have to stop the spindle and then change gear lever to get different spindle speeds.

Model "VS"------ Variable Speed Lathe

This model VS represents Variable Speed Lathe. A frequency inverter is installed to control speed of the main motor and spindle speed. The operator can easily change the spindle speed from zero to highest speed with a small potentiometer stepless rotary switch. To have strong cutting force there are three gear steps to have different gear ratio for different spindle speed requirement.

Model "M"------- Clutch Lathe

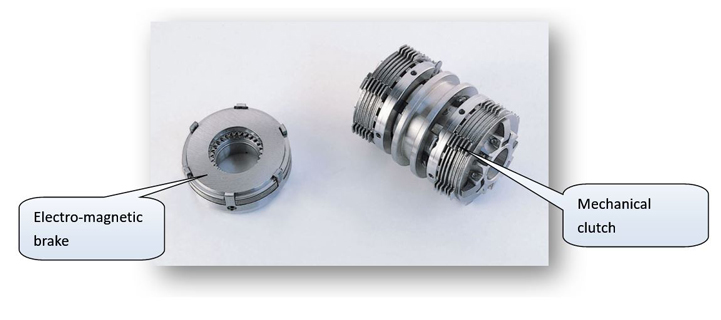

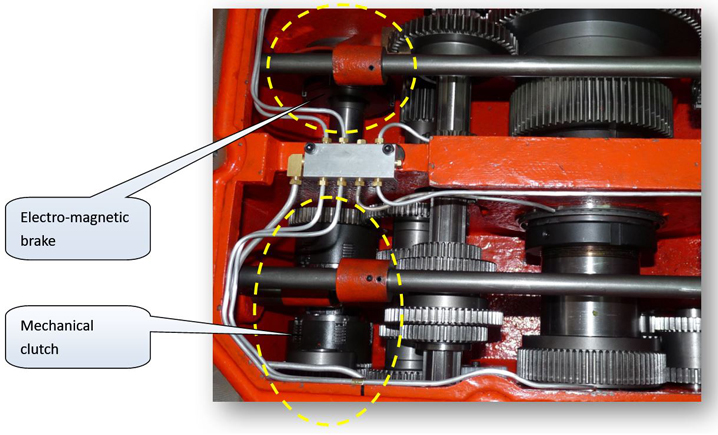

Model M is representing the manual lathes with mechanical clutch and electro-magnetic brake inside headstock. With this clutch inside headstock the operator can stop the spindle while the main motor is still running.

M series Clutch lathe is popular used for small machining process with big quantity workpieces. With mechanical clutch and electro-magnetic brake, the main spindle can stop quickly while the main motor is still running.

The clutch and electro-magnetic brake are imported from Italy which with high performance and quality.

How mechanical clutch and electro-magnetic brake works